Manual Thread Cutting Operations

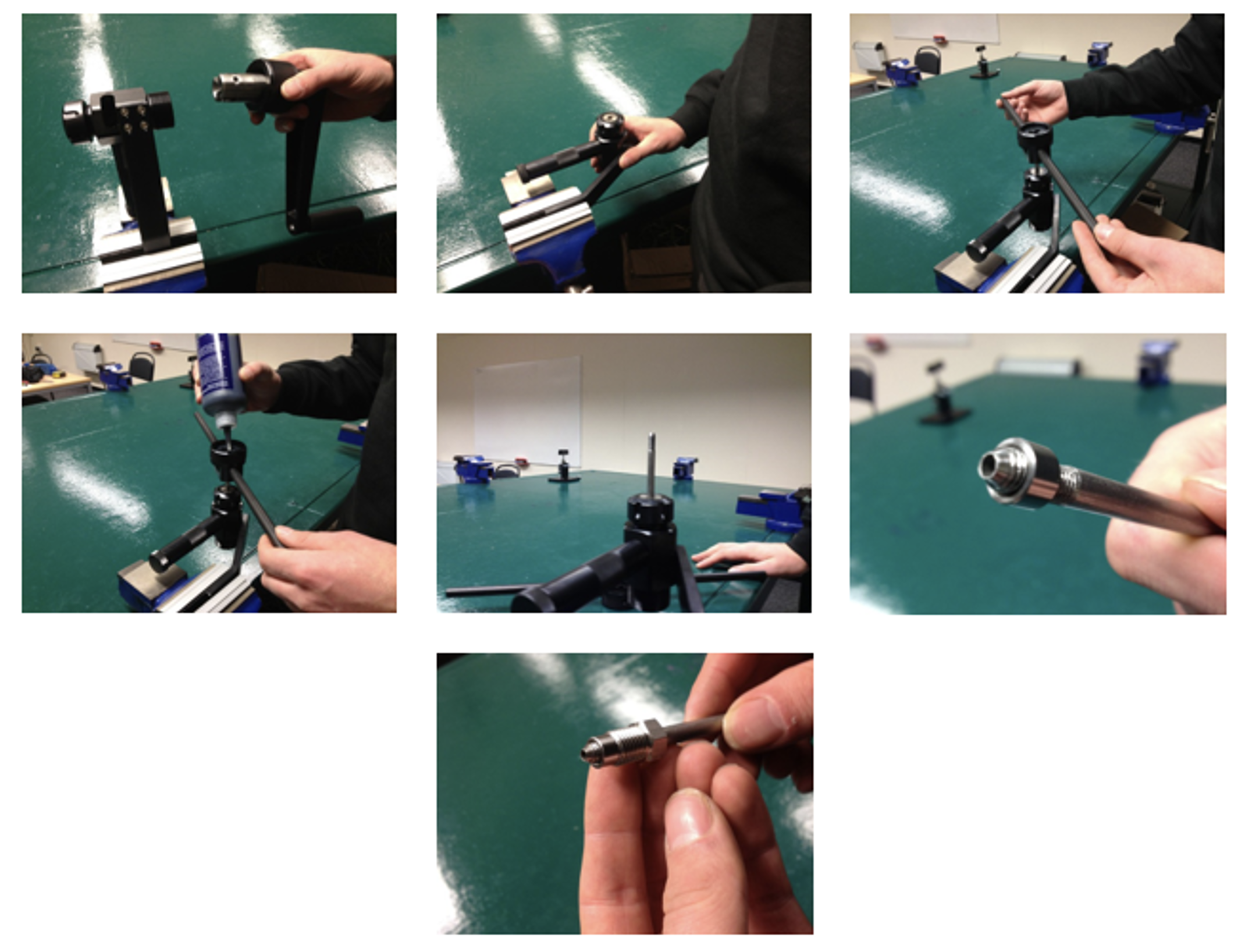

- Clamp the tubing in a vice with soft jaws or turn the tube around and place back in the collet nut and retighten. Be careful not to over tighten. Place the correct thread die and tool onto the tube use the guide bushing. Apply plenty of cutting oil to the threading area.

- Push down on the top of the threading tool and begin to turn, the threads are left handed so remember turn the die in an anti-clockwise direction. The threading tool may need to be periodically rotated clockwise to break and discharge metal chips. Again applying plenty of cutting oil during the threading operation.

- Continue cutting the thread (while applying plenty of cutting oil throughout the process) until thread has been cut to the required length.

- After the tube is coned, threaded and de-burred, check the thread by attaching a new collar of the proper size.